LASER PHOTONICS AS AN INDUSTRY – GENERAL

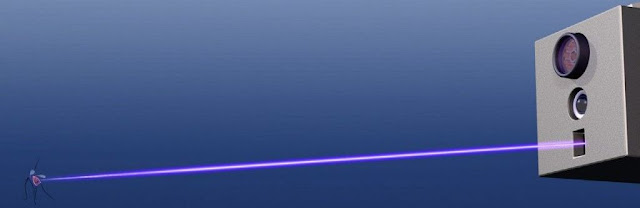

Indeed, the invention of the laser in 1960 was a pivotal moment, marking the start of the modern era of optics or photonics. This technology has since found diverse applications in various fields. During this modern era, photonic technologies have been used in a wide variety of applications including high - speed transmission, data and image storage, process and inspection monitoring, lithography, microscopy, medical procedures, calibration, spectroscopy, surveillance technologies, laser weaponry, image projection, and importantly lighting. Absolutely, photonics technologies have made substantial contributions across a wide array of industries, impacting telecommunications, semiconductors, computers, manufacturing, medicine, entertainment, and defense. Their versatility and applicability have played a pivotal role in advancing and enhancing various aspects of these industries. PHOTONICS AROUND THE GLOBE PHOTONICS SCHOOLS ECONOMIC IMPACT OF PHOTONICS Reference: SPIE, Wikipedia, Lawren...